Product Category

Rubber Springs and Hollow Rubber Bellows

Welcome to M.G.M. Rubber Company , one of the top-quality

manufacturers in India in the field of producing polymer engineering products such as Rubber Springs, Hollow Rubber Bellows, and Hollow Rubber Buffers

and many others. Leveraging our cutting-edge manufacturing technologies and implementation of advanced quality control system, we deliver highest

quality tailor made products to Railway, Heavy Vehicles industries, and various others.

At M.G.M. Rubber Company, we stand out in constructing precision Rubber Springs, Hollow Rubber Bellows, and Hollow Rubber Buffers that meet the

stringent specifications of wide range of industries. Our range of products also includes Gummy Buffers and Gear Pads, designed to perform for long

duration in dynamic applications.

With a commitment to quality and reliability, M.G.M. Rubber Company stands as a responsible partner for business houses searching for proven solution

in the field of polymer engineering products. Explore our wide range of engineering products like Rubber Springs, Hollow Rubber Bellows, and Hollow

Rubber Buffers, meticulously crafted to deliver unmatched performance and longevity in diverse environmental condition.

Experience the difference with M.G.M. Rubber Company - where the quality meets an innovation, and where customer satisfaction is the top priority.

Contact us now and discover how our Rubber Springs, Hollow Rubber Bellows, and Hollow Rubber Buffers can enhance your application to new heights of

effectiveness and performance.

What are Rubber Springs, Hollow Rubber Bellows?

Rubber Springs, Hollow Rubber Bellows, and Hollow Rubber Buffers are vital mechanical components designed to offer elasticity, cushioning, and

damping properties across diverse applications. Crafted predominantly from elastomeric materials like rubber and thermoplastic, these devices

leverage the inherent characteristics of rubber to effectively absorb and dissipate energy generated by dynamic loads or vibrations. Interestingly,

Rubber Springs, functioning based on the principles of elasticity and resilience inherent in rubber, undergo deformation under load and return to

their original shape once the load is removed. Mathematically, this behavior can be described by Hooke's Law: F=k.Δx

Where:

F is the force exerted on the spring,

k is the spring constant, representing the stiffness of the rubber spring, and

Δx is the displacement of the spring from its equilibrium position.

Additionally, rubber springs exhibit damping properties, which involve the absorption and dissipation of kinetic energy. This damping effect can be

quantified using various damping models such as the Kelvin-Voigt model or the Maxwell model.

Furthermore, rubber springs excel in vibration isolation, effectively isolating vibrations and damping shocks to enhance system stability and

performance. This capability is particularly crucial in applications where precision and smooth operation are paramount, such as in heavy machinery

or vehicle suspension systems. Actually, the versatility of rubber springs lies in their ability to be molded into various shapes and sizes,

catering to the specific requirements of different applications. This adaptability ensures optimal performance and compatibility across a wide

range of industrial and mechanical systems.

In summary, Rubber Springs, Hollow Rubber Bellows, and Hollow Rubber Buffers play a critical role in mechanical engineering, offering elasticity,

damping, and vibration isolation to enhance the efficiency, reliability, and longevity of various systems and machinery.

Construction of Rubber Springs, Hollow Rubber Bellows, Gear Pads?

The construction of Hollow Rubber Springs, Hollow Rubber Bellows, and Gear Pads by M.G.M. Rubber Company epitomizes engineering excellence,

tailored for diverse suspension system applications. These components serve as pivotal elements in suspension systems, providing crucial support

and damping characteristics alongside primary springs.

Hollow Rubber Springs boast superior deflection values and energy absorption rates, making them ideal candidates for shock absorption and damping

duties. The spring rate, a measure of stiffness, increases progressively with deflection, ensuring optimal performance across varying loads and

conditions. This behavior can be mathematically represented by the spring rate equation: k=F/δ

Where:

k is the spring rate,

F is the applied force, and

δ is the deflection.

Furthermore, these springs exhibit exceptional damping properties, effectively dissipating kinetic energy to mitigate vibrations and shocks. Their

excellent flex fatigue life ensures long-term durability and reliability, even in demanding operating environments.

Ease of installation is another hallmark of Hollow Rubber Springs, facilitating seamless integration into suspension systems. To enhance fitment

convenience, we provide bonded metal inserts, typically made of mild steel, at the top center of the part. These inserts ensure secure attachment

and optimal load distribution. In specialized applications, stainless steel inserts or bushes may be utilized to meet specific performance

requirements.

Customization is a key feature of our products, allowing for tailored solutions to suit individual user requirements. By adjusting the design or

increasing rubber wall thickness, the load carrying capacity of the rubber spring can be easily modified. This flexibility enables us to deliver

bespoke solutions that precisely match the needs of our customers, ensuring optimal performance and satisfaction.

To summarise, M.G.M. Rubber Company's Hollow Rubber Springs, Hollow Rubber Bellows, and Gear Pads represent the pinnacle of engineering innovation,

offering unmatched durability, performance, and versatility in suspension system applications.

Where are Rubber Springs, Hollow Rubber Bellows, Gear Pads used?

Rubber Springs, Hollow Rubber Bellows, and Gear Pads serve as indispensable components across a diverse array of industries, spanning railways,

automotive, aerospace, construction, industrial machinery, and transportation sectors. These versatile solutions are instrumental in various

applications, including vehicle suspensions, machinery mounts, vibration isolators, damping systems, and more, where the need for cushioning,

vibration control, and shock absorption is paramount.

In automotive settings, Rubber Springs play a critical role in vehicle suspensions, providing essential elasticity and damping characteristics to

ensure smooth rides and optimal handling. Hollow Rubber Bellows find applications in machinery mounts, effectively isolating vibrations and

minimizing noise transmission, thereby enhancing operational efficiency and comfort.

Similarly, in aerospace and industrial machinery, Gear Pads serve as reliable damping elements, absorbing and dissipating kinetic energy to

safeguard critical components and enhance overall system performance. Their weather resistance and durability make them ideal choices for demanding

environments where reliability is non-negotiable.

One of the key advantages of Rubber Springs, Hollow Rubber Bellows, and Gear Pads lies in their versatility. Their ability to adapt to varying load

conditions, environmental factors, and performance requirements makes them indispensable across a wide range of mechanical systems and

applications.

In summary, Rubber Springs, Hollow Rubber Bellows, and Gear Pads are indispensable components in modern engineering, offering a blend of elasticity,

damping, isolation, corrosion resistance, and versatility. Their widespread adoption across diverse industries underscores their importance in

ensuring the efficiency, reliability, and safety of mechanical systems worldwide.

What is our scope of manufacturing?

Our scope of manufacturing incorporates various Rubber Springs, Hollow Rubber Bellows, Hollow Rubber Buffers, Gummy Buffers, and Gear Pads, every

designed to fulfil the requirement of various industries and their application condition.

Rubber Springs: We focus on production of tailor-made Rubber Springs for vehicle suspensions, equipment mounts, and secondary

vibration isolation systems. Our Rubber Springs are engineered to exhibit matching elasticity, damping property, and longevity, making top of the

line performance in various conditions. We offer variety of Rubber Spring designs, which includes single step and multi-step profile, to

accommodate service conditions. Customization to change the load carrying capacity and stiffness characterises of the Rubber Springs as per user

requirement is available.

Hollow Rubber Bellows: Our Hollow Rubber Bellows are expertly crafted to offer efficient damping and shock protection for numerous

industries. Designed to resist dynamic movements and function in varied environmental condition, our Hollow Springs ensure dependable performance

and longevity. We provide Hollow Rubber Bellows in different sizes, shapes, and material to reduce sudden shocks and vibrations. Our Hollow Spring

Bellows are designed to resist wear, tear, and corrosion, providing exceptional durability and reliability even in harsh operating condition.

Hollow Rubber Buffers and Gummy Buffers: Our Hollow Rubber Buffers and Gummy Buffers are engineered to offer cushioning, shock

absorption, and vibration damping in heavy vehicle system. These buffers efficiently reduce noise, decrease effect of impact forces, and protect

sensitive components from getting damaged. We provide a range of Hollow Rubber Buffers and Gummy Buffers in unique sizes and hardness to satisfy

application condition. Our buffers are designed for easy set up and long performing, ensuring superior safety and efficiency in various commercial

settings.

Gear Pads: Our Gear Pads are meticulously manufactured to provide reliable damping and protection for gears of railway, automobile,

and machinery parts. Engineered to absorb and dissipate kinetic energy, our Gear Pads limit wear and tear, prolonging the lifespan of crucial

equipment. We provide Gear Pads in numerous forms, such as rubber and thermoplastic, to accommodate exceptional load capacities and running

situations. Custom designs features are available to address specific necessities.

In summary, our production capabilities in Rubber Springs, Hollow Rubber Bellows, Hollow Rubber Buffers, Gummy Buffers, and Gear Pads encompass a huge variety of products tailor-made for Railways and Heavy Vehicle applications. With a focus on high-quality, longevity, and overall performance, we attempt to offer progressive solutions that meet the evolving needs of our customers.

For detailed information, including mechanical drawings and technical data sheets for each product, simply click on the respective link provided below the product description. At M.G.M. Rubber Company, we are committed to deliver top notch solutions that meet the application & technical requirrement of our clients. Contact us right now to learn more about our products and how it can optimize the performance and longevity of your vehicle, machinery and equipment.

.webp)

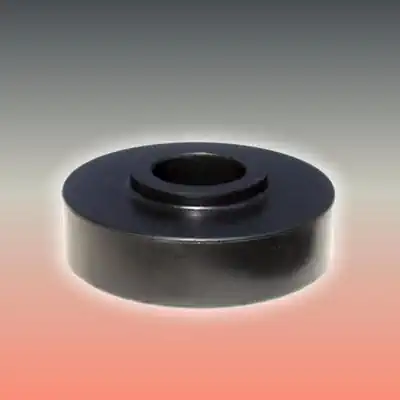

Rubber Spring

All Rubber Bellow

Hollow Rubber Spring

All Rubber Bellow

.webp)

Gummy Buffer

Hollow Buffer

Rubber Spring for FIAT

Rubber-Metal Bonded Bellow

Gear Pad

Hollow Buffer